In respect of Numerically Controlled Machining (CNC - Computerized Numerical Control), we offer, i.a. the following services:

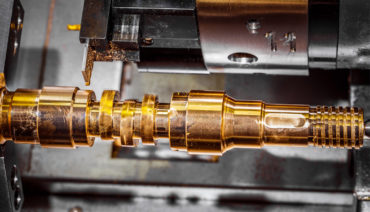

CNC turning

Thanks to high quality CNC turning lathe, we may meet the highest and the most atypical expectations of our customers as regards precise numerically controlled turning. We have high-class turning devices at our disposal and thanks to the highly qualified team, we can ensure the greatest accuracy and precision in respect of shape and dimensions.

CNC milling

Use of numerically controlled milling machines enables extremely precise treatment of material by a wide range of cutters of various thickness and shape. The details we create are characterised by a perfect shape, repetitiveness and perfect precision of production.

CNC thread cutting

Our equipment enables precise, quick and repeatable threading of various plastics and materials. We specialise in creation of internal and external threads, the parameters of which are always in compliance with the individual needs of our customers.

CNC drilling

Taking into consideration the satisfaction and various needs of our customers, we offer CNC drilling in various plastics and materials and we guarantee perfect precision and repetitiveness. Our numerically controlled driller machines enable drilling holes of typical and non-standard parameters and perfectly smooth edges. In everyday work, drills of various type are used, which enables making perfect holes, regardless of the type of the material subjected to treatment.

We subject to CNC treatment materials of many different types, for instance: Titanium, Steel, Aluminium, Copper, plastics, etc.