Why Worktech?

Because we always find solutions that make impossible possible

Phone: +48 506 055 559

Email: office@worktech.pl

WORKTECH

Łukówiec 100, 05-480 Karczew, Poland

Life is not perfect... if it was, there would be no need to do anything. Every one of us wants to work as little as possible. Do less, achieve more. Sounds familiar? Seems unreal? And yet it is possible.

If you worry every day your capping head stops working, our solution will give you peace of mind.

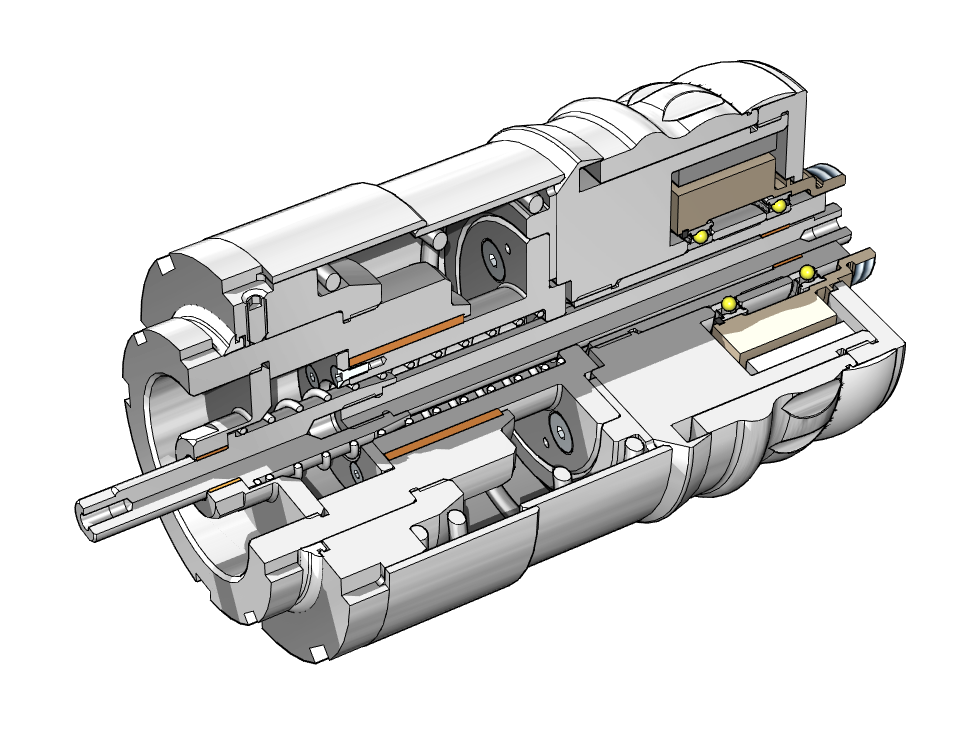

FluentSpin capping head moves smoothly, is reliable and aseptic - it has three qualities of a perfect capping head.

FleuntSpin has been constructed on the basis of an advanced hysteresis clutch with the unique system of magnets, ensuring smooth transmission of torque from the capping machine to the cap without stroke.

The transmitted torque does not depend on the rotational speed, like in case of heads with a mechanical or magnetic clutch without hysteresis.

Lack of friction parts makes the construction durable compared to the traditional solutions, the use of the highest quality materials in the head construction, including titanium and polytetrafluoroethylene ensures its long and trouble-free operation.

We also decided to ensure asepticity – the head is completely free from lubricant, there are no elements require lubrication, therefore it is not possible that any substances could constitute contaminants in a production process leak.

Cleaning of the head does not require disassembly, the head can be cleaned as a whole and sterilised in an autoclave.

Tightening torque is adjusted with a handy ring, there is no need to use any tools, bare hands are enough to adjust the force.

Histerezowa głowica FluentSpin zawiera w sobie wiele nowatorskich rozwiązań niedostępnych obecnie na rynku.

- The head does not include any elements that require lubrication, which improves its asepticity and eliminates the need of service in this respect. The head may be cleaned as a whole in high temperatures and sterilised in autoclave.

- All gaskets of the device are made of polytetrafluoroethylene, as a result, during operation, all elements move causing vary low friction, at the same time maintaining very good tightness of connection.

- Resistance to cleaning fluids and high temperature.

- The device is resistant to cleaning fluids and high temperature.

- Tightening torque adjusted smoothly (0.5 - 2.2 Nm) with a handy ring, without the need to use any tools, precise adjustment makes it possible to set the required torque with an accuracy of 0.02 Nm.

| Technical data | FluentSpin | |

|---|---|---|

| Tightening torque range | Nm | 0,5 – 2,2 |

| Working temperature | °C | -40 ± 210 |

| Weight | kg | 5,8 |

| Head pressure force | N | 165-255 |

| Cap thread maximum height | mm | 15 |

| Maximum rotational speed | rpm | 500 |

| Height without connections | mm | 167 |

| Total height | mm | 204 |

| External diameter | mm | 99 |

While designing the head, we consulted many times persons responsible for maintenance and heads adjustment and repair.

We decided to develop a head that a user can forget about after instaling it. We kept our word.

We are so sure of our solution that we offer every potential customer an option to test the head before buying it.

If you are interested in such a test – please fill in the form.

If you need to contact our advisor quickly, you can call:

+48 664 005 054