In Worktech, a separate research & development department has been created, the task of which is to develop and introduce innovative technologies as elements of the carried out activity.

The department carries out industrial research aimed at acquiring new knowledge that may be used in practice in a specific way, as well as development works, the purpose of which is using the knowledge we already have to develop new products and processes or significant improvements of the existing ones.

R&D research is carried our as part of both our own project and to fulfil the needs of our customers.

Within the framework of R&D, we carry out research in 3 main areas:

- basic research - the theoretical and experimental works, carried out for the purpose of acquiring and extending the knowledge about the causes of phenomena and facts, they are generally not focused on practical application.

- applied research - research works carried out for the purpose of acquiring new knowledge with practical application.

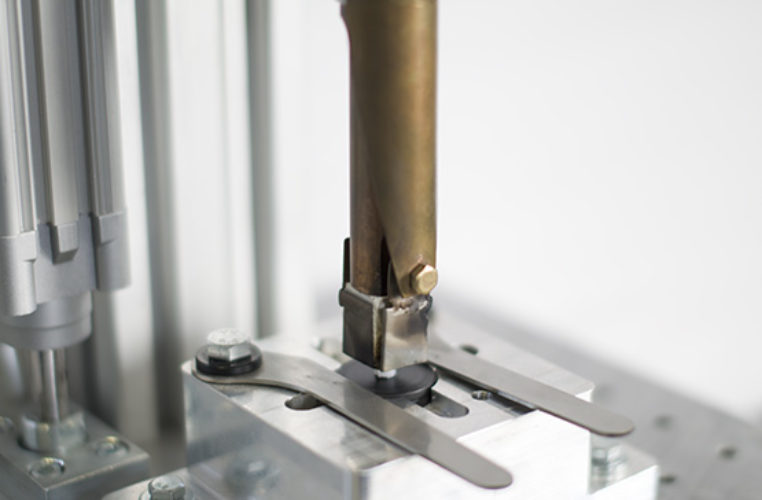

- experimental development - especially construction works, project and technology related works and experimental works, which consist in the use of the already existing knowledge for the purpose of developing new materials, devices, products, processes, systems or services, including preparation of prototypes and pilot instalations or significant improvement of the already existing ones.